Mesin penekan tablet ialah mesin yang direka bentuk untuk memampatkan bahan serbuk dan berbutir menjadi pil berbentuk bulat, bujur atau tidak sekata, satu fungsi penting untuk pembuatan tablet farmaseutikal dan pengeluaran suplemen diet. Dalam setiap kitaran penekan tablet, rod penebuk atas dan rod penebuk bawah menyelam ke dalam lubang acuan yang sama untuk memampatkan bahan serbuk ke dalam tablet di dalam lubang acuan.

Output yang tinggi nampaknya merupakan ciri paling cemerlang bagi mesin press tablet berkelajuan tinggi. Selain kapasiti pengeluaran yang mengagumkan, bagaimanakah mesin press pil automatik ini dapat menjimatkan kos anda dan sentiasa membawa lebih banyak faedah kepada anda? Kami pertama sekali menerangkan kategori mesin press pil, kemudian memberikan pandangan tentang ciri-ciri mesin press pil berkelajuan tinggi yang mencipta kelebihan unggul. Jika anda sedang mencari mesin press pil dan tablet, artikel ini mungkin memberi anda pilihan yang lebih bijak.

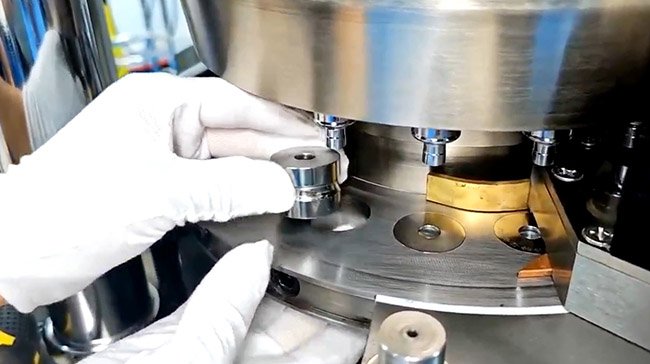

mekanisme utama (penebuk dan turet) mesin tekan pembuat pil putar berkelajuan tinggi

Mesin tekan tablet tekan pil dikelaskan kepada 2 jenis mengikut struktur mekanikal dan bentuk gerakannya.

Mesin tekan tablet mini tebuk tunggal ialah mesin pembuat tablet kimia atau farmaseutikal yang memampatkan serbuk atau granul menjadi tablet melalui hanya satu tebuk atas dan satu tebuk bawah. Ia digunakan untuk pengeluaran tablet kelompok kecil, penyelidikan makmal atau ujian berskala rintis, biasanya digunakan di farmasi, makmal dan beberapa bengkel kecil.

Mesin tekan tablet pil putar direka khas untuk pembuatan tablet berskala besar, mampu menghasilkan ratusan ribu tablet nutraseutikal atau farmaseutikal sejam dengan menggunakan turet berputar yang dilengkapi dengan berpuluh-puluh penebuk dan acuan. Di samping itu, mesin pembuatan tablet putar beroperasi dalam kaedah automatik, yang penting untuk pengepresan tablet yang cekap.

Dari segi model berputar, mesin tekan pil tablet dikelaskan kepada 2 jenis mengikut kelajuan operasinya.

Turet bulat, yang menggabungkan semua acuan dan dalam kes tertentu menanggung daya mampatan rod penebuk, merupakan salah satu komponen paling kritikal bagi mesin tekan tablet putar automatik Mesin tekan tablet pembuat pil dengan kelajuan putaran turet lebih rendah daripada 30 pusingan seminit (RPM) dikelaskan sebagai model berkelajuan rendah, manakala mesin tekan tablet dengan kelajuan putaran turet antara 30 hingga 50 RPM dikategorikan sebagai pemampat pil berkelajuan sederhana. Biasanya, output pengeluaran mesin tekan tablet berskala kecil berkelajuan rendah adalah antara 13,200 hingga 37,800 tablet/jam.

Model dengan kelajuan putaran turet melebihi 50 RPM dikategorikan sebagai mesin tekan tablet berkelajuan tinggi. Ambil HGZP 26-40D model sebagai contoh. Dengan kelajuan turet maksimum yang mencapai 110 RPM, mesin tekan tablet putar berkelajuan tinggi ini boleh mengeluarkan sehingga 260,000 tablet sejam secara automatik, sesuai untuk pembuatan tablet farmaseutikal berskala besar.

Menyemak mesin tekan pil mewah dikeluarkan oleh pembekal jentera farmaseutikal peringkat tinggi seperti IMA, Romaco, dan Pembungkusan Kaya , output maksimum mesin cetak tablet berkelajuan tinggi boleh mencecah 960,000 tablet sejam.

Selain output yang tinggi, apakah kelebihan yang dibawa oleh mesin cetak tablet berkelajuan tinggi? Bagaimanakah mesin ini dapat menjimatkan kos dalam pengeluaran tablet jangka panjang anda? Kita akan mendalami ciri-ciri pembuat pil yang canggih.

Berbanding dengan model berkelajuan rendah, penekan pil berkelajuan tinggi menawarkan pelbagai faedah luar biasa yang sangat penting dengan kualiti tablet, pengurangan masa henti, jangka hayat peralatan yang lebih lama, pematuhan peraturan, dan sebagainya. Selain output yang tinggi, kami akan menyebut 5 faedah kritikal:

1) Kawalan berat tablet yang tepat

2) Kemudahan pertukaran perkakas dan penjimatan masa henti

3) Kaedah pelinciran automatik dan jangka hayat mesin yang lebih lama

4) Pemampatan tablet bebas habuk dan penjimatan bahan

5) Pengurangan hingar semasa menekan tablet

Kebanyakan mesin cetak tablet berkelajuan tinggi di pasaran pada masa kini menikmati kawalan berat tablet masa nyata, automatik dan tepat, manakala pemampat tablet berkelajuan sederhana atau rendah bergantung pada pelarasan berat tablet secara manual melalui roda tangan.

Melalui skrin sentuh, parameter boleh dilaraskan dan tekanan boleh dipantau.

Apabila ia berkaitan dengan keseragaman berat tablet, Piawaian cGMP tetapkan keperluan yang jelas untuk menguruskan berat tablet: Adalah wajib untuk memastikan berat tablet yang konsisten bagi menjamin keseragaman kelompok dan ketepatan kandungan. Pengilang tablet penekan pil dikehendaki mencapai matlamat ini melalui pemantauan proses pengeluaran tablet, yang menentukan bahawa penekan tablet berputar mesti mempunyai ketepatan dan automasi yang tinggi dalam kawalan berat tablet.

Bagi memenuhi keperluan cGMP, pengeluar mesin penekan tablet merekayasa mesin penekan pil berkelajuan tinggi yang menjalankan kawalan berat tablet masa nyata semasa proses penekan pil. Kawalan ini dicapai melalui 3 fungsi:

Semasa pemampatan tablet, sensor yang dipasang pada gulungan mampatan dan rod penebuk mengukur daya yang ditanggung oleh setiap penebuk dalam masa nyata. Turun naik yang tidak normal dalam daya mampatan wujud sebagai petunjuk awal sisihan berat tablet. Contohnya, penurunan tekanan secara tiba-tiba mungkin menunjukkan isipadu isian serbuk yang tidak mencukupi, mengakibatkan tablet ubat kurang berat, manakala peningkatan tekanan secara tiba-tiba menunjukkan isipadu isian yang berlebihan, yang membawa kepada tablet ubat yang berlebihan berat.

Fungsi ini bergantung pada maklum balas tekanan. Jika sensor mengesan sisihan daya mampatan daripada nilai sasaran, sistem melalui motor servo akan serta-merta mengeluarkan arahan untuk membuat pelarasan halus secara automatik pada kedalaman pengisian pengumpan. Pelarasan ini meningkatkan atau mengurangkan isipadu serbuk dalam lubang acuan, mengembalikan tekanan kepada nilai yang ditetapkan, sekali gus mencapai berat tablet yang konsisten.

Sistem ini secara automatik mengenal pasti mana-mana tablet yang menyimpang daripada parameter tekanan yang ditetapkan dan menolaknya dengan tepat. Dengan sentiasa mengeluarkan tablet individu yang kurang berat atau berlebihan berat, mesin penekan tablet automatik memastikan tablet ubat siap dengan berat yang konsisten.

Pada sesetengah mesin cetak tablet pil berkelajuan sederhana dan rendah, fungsi di atas mungkin merupakan ciri pilihan. Kebanyakan model ini masih bergantung pada persampelan berkala, pemeriksaan berat selepas pengeluaran tablet dan pelarasan manual, yang dianggap sebagai kawasan risiko dalam audit cGMP. Sebaliknya, mesin cetak pil berkelajuan tinggi biasanya menikmati pemantauan daya tebukan dan pelarasan isipadu serbuk automatik, yang mewakili peralihan daripada ujian pasca pengeluaran kepada kawalan proses masa nyata.

Sebagai pengeluar farmaseutikal, anda mengeluarkan beberapa atau beberapa jenis tablet. Setiap kali sebelum anda menekan jenis tablet yang lain, anda perlu menukar acuan anda termasuk rod penebuk dan acuan untuk pembersihan dan menggunakan bentuk baharu pada tablet farmaseutikal, mengakibatkan masa henti mesin tekan tablet. Untuk mengurangkan masa henti, banyak mesin tekan tablet putar berkelajuan tinggi mempunyai fungsi penukaran acuan tanpa alat, membantu menggantikan perkakas dalam masa 30 minit.

penukaran acuan tanpa alat dengan tangan kosong

|

Ciri |

Mesin Tekan Pil Tradisional |

Mesin Tekan Pil Berkelajuan Tinggi dengan Keupayaan Perubahan Acuan Pantas |

|

Matlamat Reka Bentuk |

Kestabilan operasi jangka panjang |

Kestabilan serta fleksibiliti, pertukaran produk yang pantas, masa henti yang dikurangkan |

|

Alat Perubahan Acuan |

Diperlukan (sepana tork, bicu, dll.) |

Pada asasnya tidak diperlukan atau hanya alat mudah yang diperlukan |

|

Masa Perubahan Acuan |

Lama (beberapa jam) |

Pendek (berpuluh-puluh minit) |

|

Kos |

Peralatan itu sendiri agak rendah, tetapi kos buruh dan masa henti adalah tinggi |

Pelaburan peralatan awal yang tinggi, tetapi kecekapan perubahan acuan adalah tinggi dan masa henti dikurangkan |

|

Pengaruh pada Peralatan |

Mengetuk atau memukul menumbuk dan acuan dameges ketepatan acuan |

Penukaran acuan tangan kosong tanpa alat melindungi ketepatan acuan dan memanjangkan jangka hayat perkakas |

Mesin tekan tablet putar berkelajuan tinggi dengan reka bentuk modular pelepasan cepat, seperti HGZP 15-20D , membolehkan pertukaran acuan dan penebuk dengan tangan kosong, sekali gus mengurangkan masa henti mesin dengan ketara. Tambahan pula, memandangkan alatan tidak diperlukan untuk memukul atau mencungkil acuan dan rod penebuk, ketepatan dan jangka hayat acuan lebih terpelihara.

Sebaliknya, kebanyakan mesin tablet ubat berkelajuan rendah kekurangan fungsi penukaran acuan tanpa alat. Sebaliknya, alat seperti tukul, bicu dan sepana mesti digunakan untuk membuka acuan dan penebuk dengan memukulnya. Akibatnya, pukulan ini mudah menekan serpihan logam, melibatkan intensiti tenaga kerja yang tinggi dan mengakibatkan masa henti yang berpanjangan. Tambahan pula, pukulan jangka panjang mengubah bentuk lubang acuan bulat menjadi lubang acuan bujur, yang mengakibatkan kehilangan ketepatan perkakas dan mengganggu proses pembuatan tablet.

Hasil daripada penggantian acuan tanpa alat, jika anda menggunakan mesin mampatan berkelajuan tinggi untuk tablet dalam pembuatan tablet, sekurang-kurangnya 2 jam boleh dijimatkan dalam setiap pusingan pertukaran acuan. Dengan mengandaikan acuan perlu ditukar seminggu sekali, dan terdapat sekitar 50 minggu setahun, sejumlah 100 jam boleh dijimatkan untuk pertukaran acuan setiap tahun. Dengan kadar pengeluaran sebanyak 150,000 tablet ubat sejam, masa yang dijimatkan akan membolehkan tambahan 15 juta tablet farmaseutikal dihasilkan dalam setahun.

Sistem pelinciran pintar biasanya terdapat dalam pemampat tablet berkelajuan tinggi. Ciri ini juga merupakan konfigurasi standard dalam mesin tablet putar berprestasi tinggi moden. Walau bagaimanapun, dalam kes yang kerap menggunakan model berkelajuan rendah, pengguna perlu melincirkan secara manual.

|

|

Pelinciran Pintar |

Pelinciran Manual |

|

Teori Kerja |

Dikawal oleh PLC untuk menghantar pelincir secara automatik, tepat pada masanya dan kuantitatif ke titik pelinciran melalui saluran minyak. |

Bergantung pada buruh manual menggunakan alat seperti berus atau tin semburan untuk aplikasi |

|

Ketepatan Pelinciran |

★★★★★ |

★ |

|

Kecekapan |

★★★★★ |

★ |

|

Pemeliharaan Peralatan |

★★★★★ |

★★ |

|

Penjimatan Kos Buruh |

★★★★★ |

★ |

|

Penjimatan Pelincir |

★★★★★ |

★ |

|

Pemantauan Masa Nyata |

✔ |

✘ |

Sistem pelinciran pintar terbina dalam menggunakan teknologi kawalan automatik untuk menghantar pelincir tepat kepada komponen yang diperlukan mengikut masa dan ukuran. Berdasarkan kerja berterusan, ia melincirkan bahagian peralatan tanpa menghentikan pengeluaran tablet, memastikan proses pembuatan tablet yang tidak terganggu. Tambahan pula, pelinciran pintar menghalang haus peralatan yang disebabkan oleh gangguan bekalan minyak, memanjangkan hayat perkhidmatan komponen kritikal seperti gulungan mampatan, penebuk dan trek. Terima kasih kepada pelinciran automatik dan tepat, ia juga mengurangkan kos buruh dan penggunaan pelincir.

Sebaliknya, pelinciran manual terdedah kepada pengagihan pelincir yang tidak sekata disebabkan oleh faktor manusia, yang sering mengakibatkan pelinciran berlebihan atau kekurangan. Selain itu, ia memerlukan penutupan mesin, yang menghalang kecekapan pemampatan tablet. Tambahan pula, kaedah ini sangat bergantung pada ketekunan pengendali, dan pelinciran yang tidak mencukupi menyebabkan haus komponen, sekali gus mengurangkan jangka hayat mesin pemampatan tablet farmaseutikal.

Dalam operasi pemampatan tablet tradisional, pelepasan serbuk yang tidak terkawal di dalam ruang pemampatan merupakan cabaran biasa. Fenomena ini mengakibatkan kehilangan bahan serbuk dan pencemaran silang produk, serta bercanggah dengan keperluan cGMP.

Untuk menangani isu ini, mesin pemampatan tablet berkelajuan tinggi moden boleh mengintegrasikan pelbagai penyelesaian kejuruteraan untuk mencapai pembendungan serbuk dan habuk. 4 mekanisme utama digunakan untuk kawalan serbuk dan habuk:

Ia menggantikan pengumpan terbuka dalam mesin pembuat pil berkelajuan rendah tradisional. Sistem tertutup ini memastikan serbuk dimuatkan dan dipaksa masuk ke dalam rongga acuan tanpa terdedah. Jurang ≤0.05mm yang dijaga dengan teliti antara tapak pengumpan dan turet seterusnya menghalang kebocoran serbuk.

pengumpan paksa tertutup (kiri) dan bilah penindasan serbuk (putih di sebelah kanan)

Peranti ini menangkap serbuk sisa yang keluar dari pengumpan. Dengan bantuan pemacu turet, mekanisme ini mengitar semula serbuk berlebihan untuk digunakan semula, mengekalkan permukaan turet yang bersih dan meminimumkan pembaziran serbuk.

Diletakkan secara strategik pada turet antara pengumpan dan titik di mana tebuk atas memasuki lubang acuan, bilah ini secara fizikal menghalang serbuk daripada terkeluar dari rongga acuan disebabkan oleh putaran turet yang pantas.

Mempunyai mekanisme sekurang-kurangnya 12 port sedutan yang diletakkan di sekitar perimeter turet, peranti ini secara aktif menangkap serbuk atau habuk yang terlepas daripada langkah pembendungan lain.

Secara kolektifnya, sistem kawalan serbuk bersepadu ini mengubah pemampatan tablet berkelajuan tinggi daripada operasi berdebu kepada proses pembuatan tablet yang bersih.

Untuk mengurangkan haus tebukan dan bunyi operasi, mekanisme redaman adalah standard dalam mesin mampatan tablet putar berkelajuan tinggi. Walaupun kurang biasa pada model berkelajuan rendah, ia dijangka akan semakin popular secara beransur-ansur.

rod penebuk atas dan bawah

Dipasang di sekeliling rod penebuk, komponen ini menggunakan bahan elastik untuk menyerap tenaga getaran. Dengan meredam getaran yang bergerak melalui rangka mesin, ia berkesan menghalang getaran ini daripada menjadi bunyi bawaan udara.

Sistem ini menghasilkan daya brek tanpa sentuh. Magnet tetap diletakkan berhampiran hujung laluan pergerakan penebuk, berinteraksi dengan magnet pada penebuk untuk menghasilkan daya tolakan. Ini mengakibatkan nyahpecutan secara beransur-ansur dan "hentian lembut", menghapuskan bunyi hentaman yang biasanya disebabkan oleh perlanggaran mekanikal.

Struktur redaman ini menyerap tenaga hentaman daripada tumbukan yang berlanggar dengan panduan turet, mengurangkan bunyi bising sebanyak kira-kira 25 dB dan mewujudkan persekitaran yang lebih sihat untuk pengendali penekan pil. Ia juga mengurangkan daya hentaman, meminimumkan serpihan logam yang dihasilkan oleh geseran logam dan memanjangkan hayat perkhidmatan perkakas. Walau bagaimanapun, pengeluar penekan pil berkelajuan rendah tradisional biasanya tidak menerima pakai mekanisme redaman sebagai ciri standard untuk mengurangkan kos.

Semasa anda teragak-agak antara mesin cetak tablet berkelajuan tinggi dan model berkelajuan sederhana/rendah, pertimbangkan lebih banyak lagi selain harga awal dan permintaan output anda. Penilaian menyeluruh terhadap pematuhan cGMP, kawalan berat tablet, kecekapan operasi, pengurangan masa henti, pemeliharaan jangka hayat peralatan, penjimatan kos, dan sebagainya adalah perlu. Beri perhatian kepada bidang utama ini akan membimbing anda kepada mesin pil yang menjamin kualiti tablet farmaseutikal anda dan nilai jangka panjang yang mampan.