Jika anda sedang mempertimbangkan untuk meningkatkan kecekapan pengeluaran kapsul anda, a mesin pengisian kapsul automatik sepenuhnya adalah penyelesaian yang ideal. Peralatan ini dapat mengautomasikan langkah-langkah mengasingkan, mengisi dan menutup kapsul, meningkatkan kecekapan pengeluaran secara mendadak. Panduan ini akan menerangkan secara terperinci prinsip kerja, komposisi dan senario aplikasi peralatan untuk membantu anda memahami dengan lebih baik dan memilih yang betul peralatan mengisi kapsul .

1. Apakah mesin pengisian kapsul automatik?

Mesin pengisian kapsul automatik sepenuhnya adalah peralatan yang digunakan dalam industri farmaseutikal dan nutraseutikal untuk pengeluaran besar-besaran pengisian kapsul, yang boleh merealisasikan pengisian automatik ketepatan tinggi serbuk, butiran, mikropelet dan cecair ke dalam peralatan farmaseutikal kapsul. Peralatan tersebut menggantikan proses pengisian kapsul manual yang membosankan melalui satu siri program dan operasi automatik. Peralatan ini boleh mengekalkan pengeluaran berkelajuan tinggi dan berketepatan tinggi tanpa campur tangan manusia, memastikan dos yang konsisten untuk setiap kapsul.

Sebab anda mungkin memerlukan peralatan ini adalah sangat mudah: ia boleh meningkatkan produktiviti dengan ketara, mengurangkan ralat manusia dan mengurangkan kos operasi secara drastik. Jika anda ingin menghasilkan beribu-ribu kapsul seminit sambil mengekalkan tahap konsistensi yang tinggi, mesin pengisian kapsul automatik sepenuhnya adalah pilihan yang tepat untuk anda.

Cara mesin pengisian kapsul automatik sepenuhnya berfungsi dibahagikan kepada beberapa langkah utama yang disepadukan rapat untuk memastikan operasi lancar barisan pengeluaran:

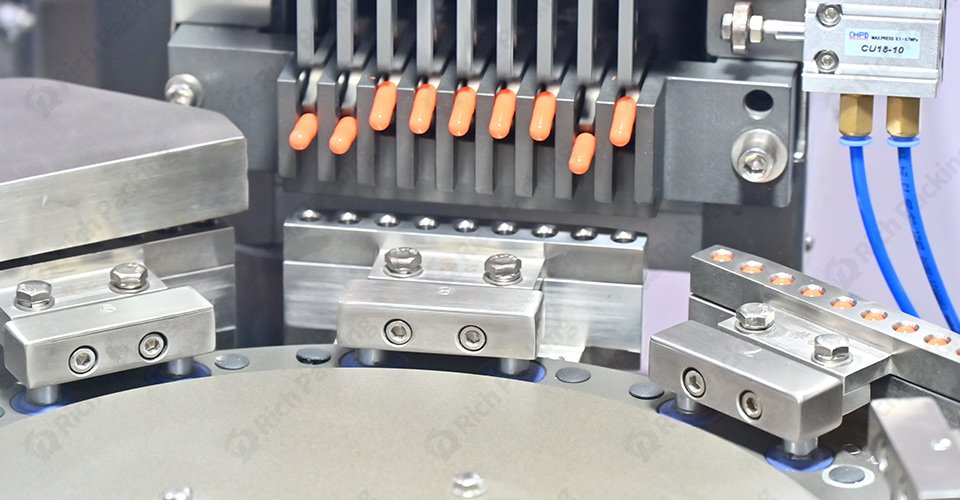

Pemisahan Kapsul: Pada permulaan operasi mesin, kapsul berongga dimasukkan ke dalam mesin pengisian. Kapsul biasanya terdiri daripada dua bahagian: penutup kapsul dan badan kapsul. Mesin pengisian kapsul memisahkan dua bahagian kapsul dengan cara sistem pemisahan yang canggih dan tekanan vakum negatif, yang secara automatik dan seragam mengarahkan kapsul berongga melalui dua bahagian kapsul dan memastikan setiap kapsul diselaraskan dengan tepat dan sedia untuk diisi.

Bahan pengisian: Sama ada anda menggunakan serbuk, butiran atau cecair, sistem pengisian akan memastikan setiap kapsul menerima dos yang sama. Sistem pengisian biasanya menggunakan cakera bergetar, cakera berputar atau peranti dos ketepatan untuk mengisi bahan ke dalam badan kapsul dengan tepat. Untuk bentuk dos kapsul yang berbeza, peralatan boleh melaraskan kaedah pengisian mengikut kesesuaian.

Menutup dan Menekan: Setelah pengisian selesai, penutup atas kapsul dipasang semula dan ditekan pada tempatnya pada badan kapsul. Langkah ini penting kerana ia memastikan penutupan dan integriti kapsul untuk mengelakkan pecah atau kebocoran dalam proses seterusnya.

Keluaran Kapsul: Kapsul siap akan dikeluarkan dari port pelepasan melalui bar atas pelepasan. Selepas kapsul telah diisi dan dikeluarkan, ia boleh digabungkan dengan mesin pengisih dan penggilap kapsul untuk membersihkan dan menggilap permukaan dan mengeluarkan sebarang kapsul berongga yang mungkin tidak diisi dengan betul. Keseluruhan proses dijalankan di bawah prosedur automatik, mengurangkan operasi manual dan meningkatkan kecekapan pengeluaran.

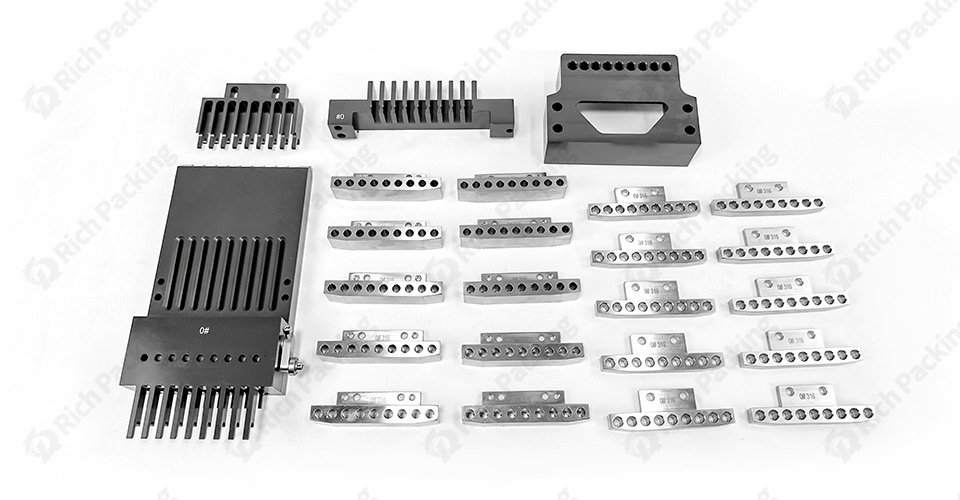

Salah satu kelebihan utama mesin pengisian kapsul automatik sepenuhnya ialah ia boleh menampung pelbagai saiz kapsul dan formulasi pengisian. Dari saiz 000 hingga saiz 5, mesin ini mampu mengendalikan pelbagai saiz kapsul dengan menukar acuan dan melaraskan parameter dalaman. Selain saiz kapsul, pengisi juga mampu mengendalikan pelbagai bentuk bahan, termasuk serbuk, butiran, dan juga cecair. Ini membolehkan mesin mengatasi formulasi farmaseutikal yang berbeza dan memenuhi pelbagai keperluan pengeluaran. Untuk bahan yang berbeza, peralatan boleh memperhalusi sistem pengisian untuk memastikan konsistensi dan ketepatan pengisian.

Operasi cekap mesin pengisian kapsul automatik sepenuhnya bergantung pada beberapa komponen teras. Di bawah ialah penjelasan terperinci tentang peralatan utama ini:

Sistem Kapsul Pemisahan: Sistem ini bertanggungjawab untuk mengasingkan penutup kapsul daripada badan kapsul. Proses pengasingan mestilah sangat tepat, terutamanya ketepatan ketumpuan topi kapsul dan acuan badan kapsul, untuk memastikan setiap kapsul diasingkan dengan betul sebelum ia memasuki proses pengisian. Sistem pemisahan yang tepat bukan sahaja meningkatkan produktiviti tetapi juga mengurangkan sekerap.

Sistem Pengisian: Sistem pengisian adalah bahagian teras mesin. Ia bertindak balas kepada pelbagai jenis bahan, termasuk serbuk, butiran dan cecair, dengan kepala pengisian yang berbeza. Cakera bergetar, cakera berputar atau peranti dos memastikan setiap kapsul menerima dos yang konsisten, sekali gus menjamin kualiti setiap produk.

Sistem Penutupan: Setelah kapsul telah diisi, sistem penutup dipasang semula dan menekan penutup ke badan kapsul. Proses ini memastikan integriti kapsul dan mengelakkan kebocoran semasa pengangkutan dan penyimpanan.

Sistem pemeriksaan dan kawalan: Mesin pengisian biasanya dilengkapi dengan sistem pemeriksaan automatik yang memantau bahan dan jumlah pengisian setiap peringkat pengeluaran kapsul dalam masa nyata untuk memastikan kualiti dan konsistensi. Jika sebarang keabnormalan berlaku, peralatan akan secara automatik berhenti atau menolak produk yang rosak secara automatik untuk mengelakkan kumpulan besar produk yang salah daripada memasuki pasaran.

Salah satu ciri utama Mesin Pengisian Kapsul Automatik ialah ia meningkatkan produktiviti dengan ketara dan mengurangkan kos operasi pada masa yang sama.

Kerana mesin itu automatik sepenuhnya, ia beroperasi pada kelajuan yang sangat tinggi dan boleh menghasilkan beribu-ribu kapsul seminit. Automasi juga mengurangkan ralat manusia dan memastikan setiap kapsul diisi dengan jumlah yang sama, dengan ketara mengurangkan kadar kegagalan produk.

Peralatan automatik sepenuhnya mengurangkan pergantungan pada buruh manual dan mengurangkan kos buruh. Di samping itu, peralatan pengisian moden sering direka untuk menjadi cekap tenaga, mengurangkan penggunaan tenaga sambil menghasilkan dengan cekap. Kemudahan penyelenggaraan juga mengurangkan masa henti dalam jangka panjang, seterusnya meminimumkan kos operasi.

Pengisi kapsul automatik sepenuhnya digunakan dalam pelbagai industri, dan cemerlang dalam bidang berikut khususnya:

Industri farmaseutikal: Industri farmaseutikal memerlukan kualiti dan kecekapan tinggi dalam pengeluaran farmaseutikal. Kapsul mesti dihasilkan dalam persekitaran aseptik untuk memastikan dos dan kualiti setiap kapsul adalah konsisten. Mesin pengisian kapsul automatik direka untuk persekitaran pengeluaran yang mencabar ini.

Industri Nutraseutikal: Dalam penghasilan nutraseutikal, vitamin, mineral dan bahan-bahan lain biasanya perlu dibuat dalam bentuk kapsul. Mesin pengisian kapsul automatik sepenuhnya membantu pengeluar nutraseutikal menghasilkan produk dengan konsistensi yang tinggi dengan cekap.

Industri makanan: Kapsul semakin banyak digunakan dalam makanan tambahan. Mesin pengisian kapsul automatik sepenuhnya adalah bahagian penting dalam barisan pengeluaran industri makanan, kerana ia membolehkan pengeluaran besar-besaran yang cepat dan cekap.

Industri kosmetik: Kapsul digunakan secara inovatif dalam produk kosmetik tertentu. Mesin pengisian kapsul automatik sepenuhnya mampu memenuhi permintaan untuk pemprosesan halus dalam industri ini.

Apabila anda bersedia untuk melabur dalam mesin pengisian kapsul automatik sepenuhnya, faktor berikut adalah penting:

Memilih mesin yang mudah diselenggara boleh mengurangkan masa henti dan kos penyelenggaraan jangka panjang dengan ketara. Mesin yang sangat dipercayai bukan sahaja akan meningkatkan produktiviti, tetapi juga akan membantu anda menjimatkan wang dalam jangka masa panjang.

Pilih model peralatan yang sesuai untuk keperluan pengeluaran anda. Barisan pengeluaran volum tinggi memerlukan peralatan berkelajuan tinggi, berkapasiti tinggi, manakala pengeluar kecil dan sederhana mungkin lebih sesuai untuk model volum rendah dan lebih fleksibel.

Perkhidmatan selepas jualan yang baik dan sokongan teknikal boleh memberikan maklum balas yang cepat sekiranya berlaku kegagalan peralatan, memastikan barisan pengeluaran anda boleh terus berjalan dengan stabil.

Pengisi kapsul automatik sepenuhnya menawarkan kelebihan ketara dari segi produktiviti dan konsistensi. Dengan panduan ini, anda telah mendapat gambaran tentang cara ia berfungsi, kandungannya dan faktor utama yang perlu dipertimbangkan semasa memilih mesin, dan diharapkan ini akan membantu anda membuat pilihan terbaik untuk keperluan pengeluaran anda.